Infrastructre

Krishna Print, a pioneer in Jetpur’s textile process house industries has set up state of the art infrastructure to process and manufacture international quality textile products.

The company has world’s most sophisticated machines to cater the demand of fabrics for domestic as well as international customers. To build up world class infrastructure for textile / fabrics processing is not enough, it should be maintained well also. You can say that Krishna Print is the most maintained textile process house, which gives consistent quality products.

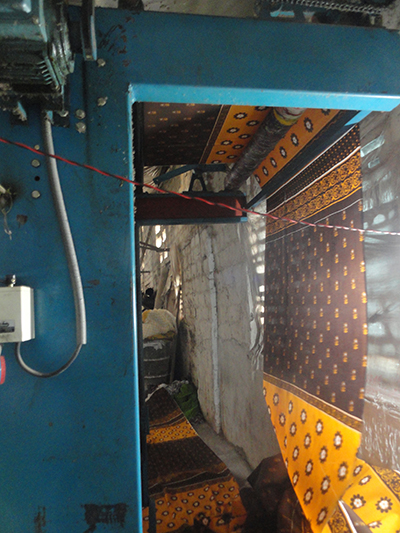

Flat bed screen printing machine

- A fully automatic flat bed screen printing machine

- Maximum capacity: 12,000 mts/day

- Fabric width ranging from 15” to 54”

- Print up to 8 colors

Curing Machine

- A semi-automatic curing machine

- Maximum capacity: 10,000 mts/day

Dyeing Machines (1 Jigger & 2 Padding Mangles)

- Fully automatic dyeing machines

- Combined maximum capacity: 40,000 mts/day

4 table screen printing units

- Each unit of 1100 sq.ft. consisting 27 meters long 12 tables

- Combined Maximum capacity: 8,000 mts/day

- Each unit quipped with its own laboratory

Hydraulic press-packing machine

- A semi-automatic packing machine to ship goods in safest way possible and durable enough even for export.